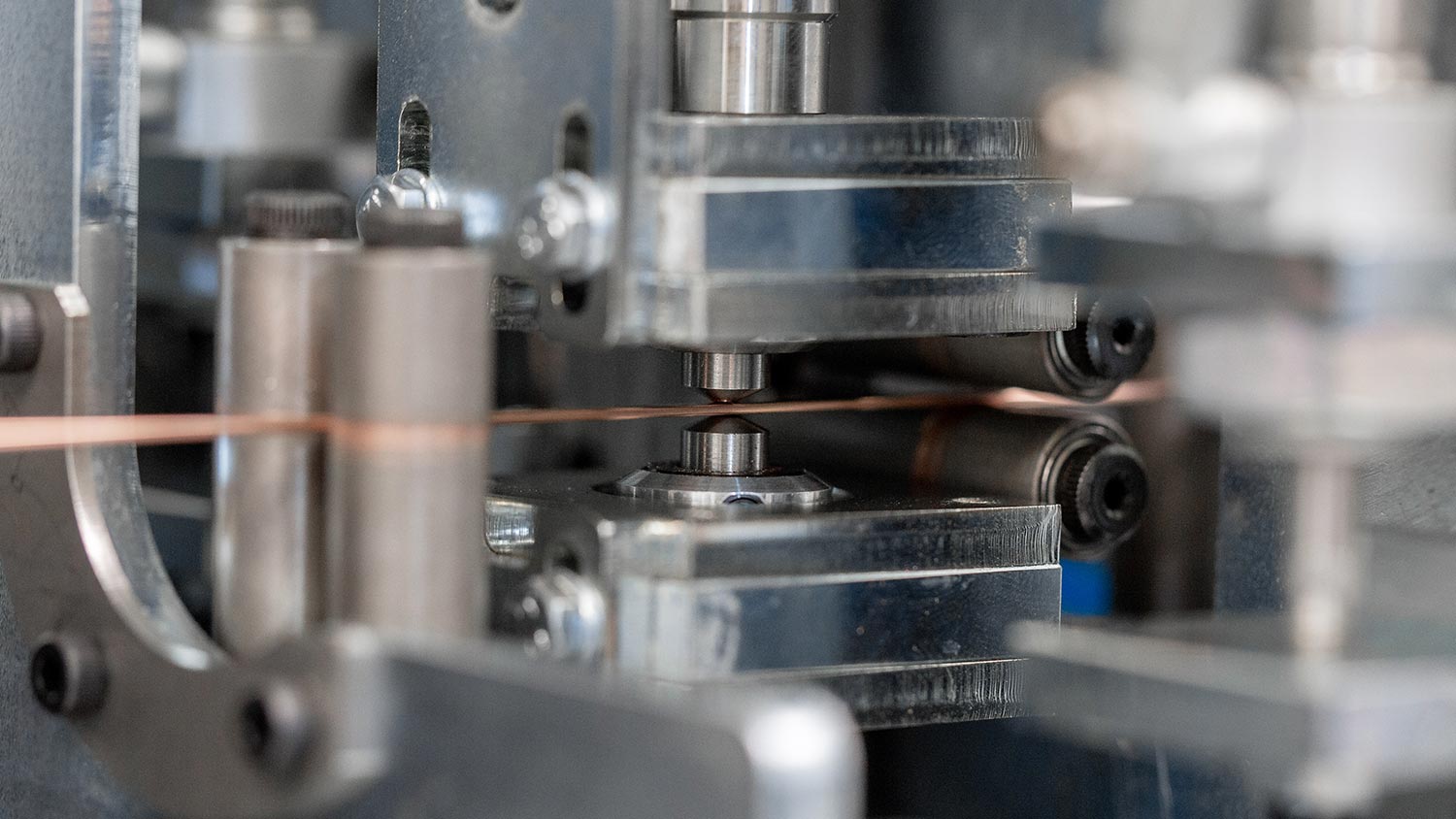

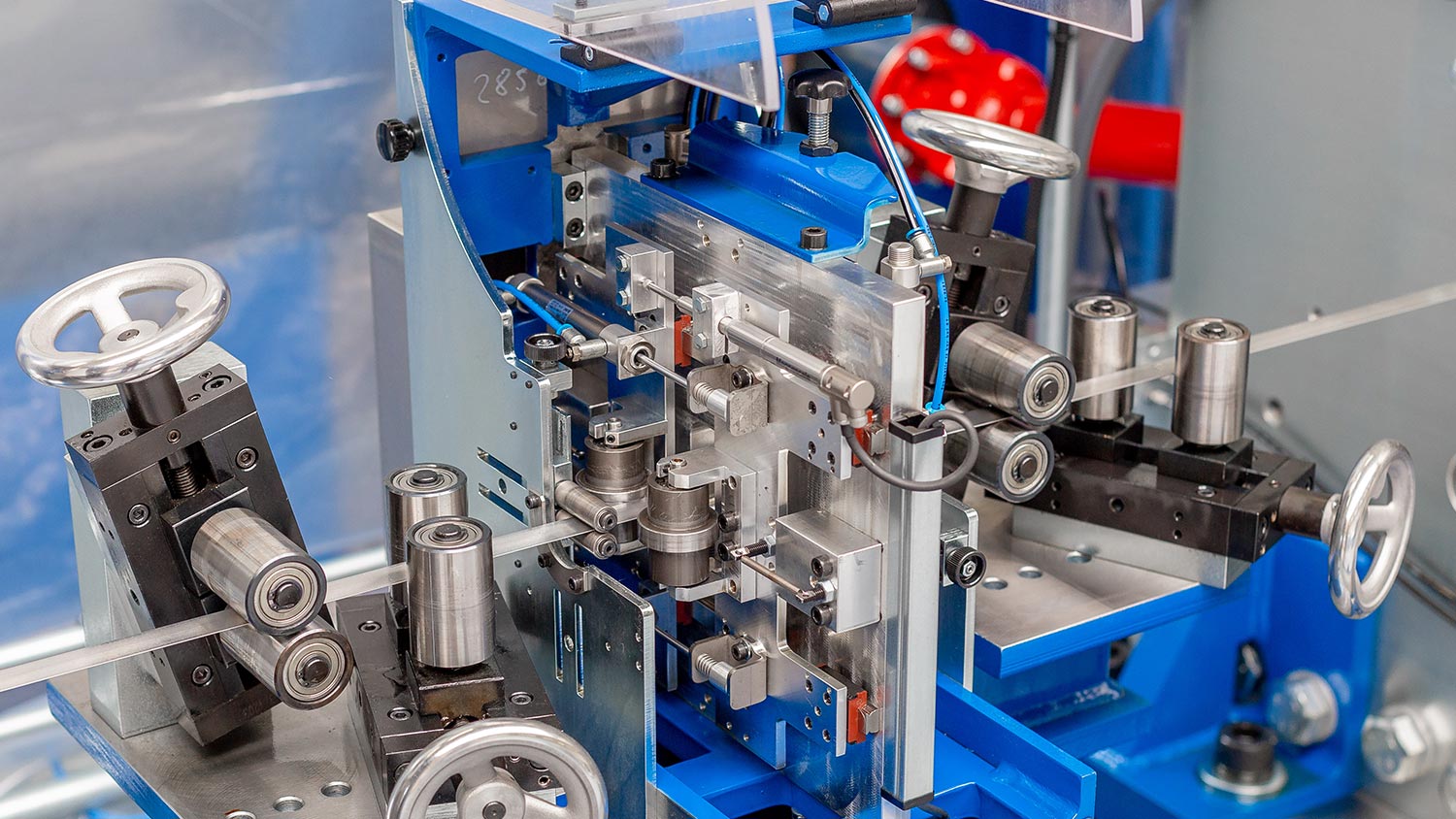

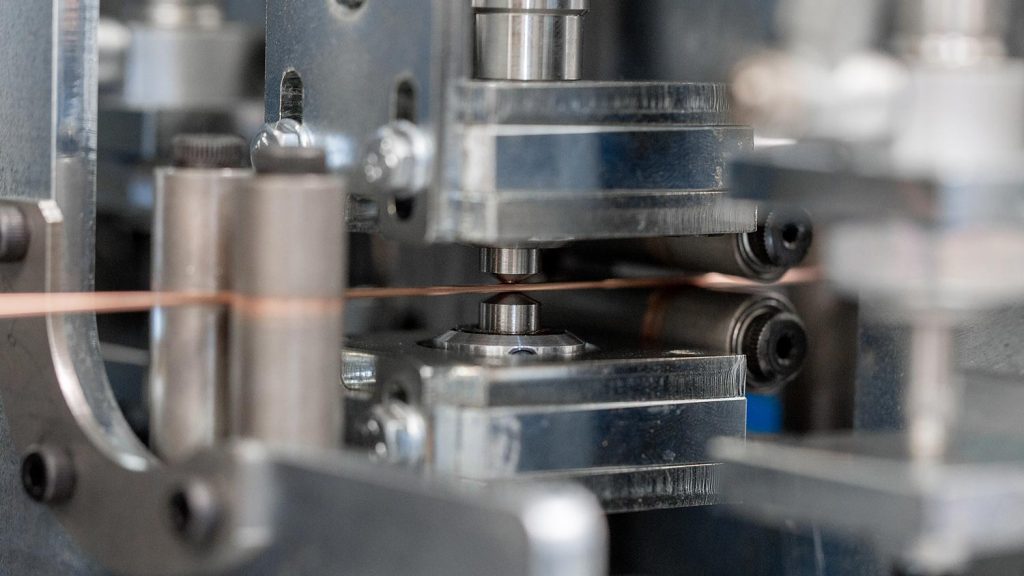

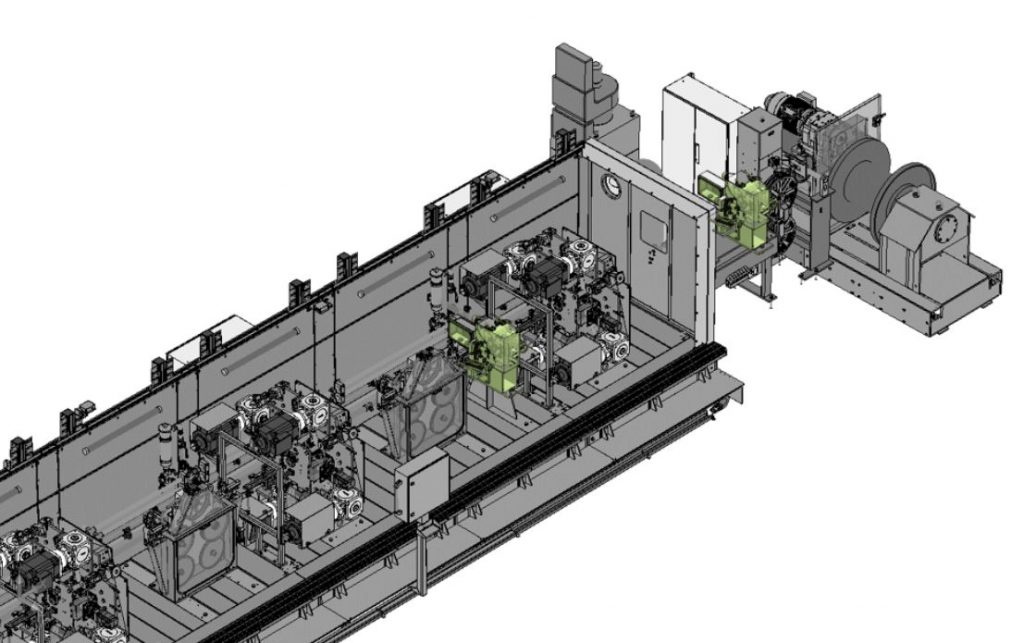

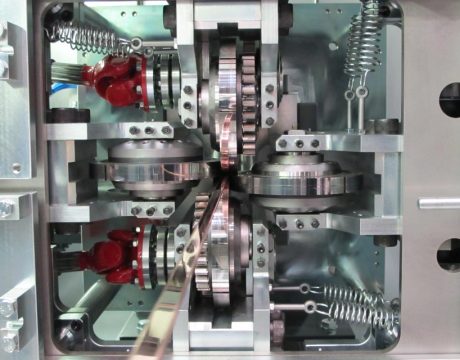

Inline measurement system

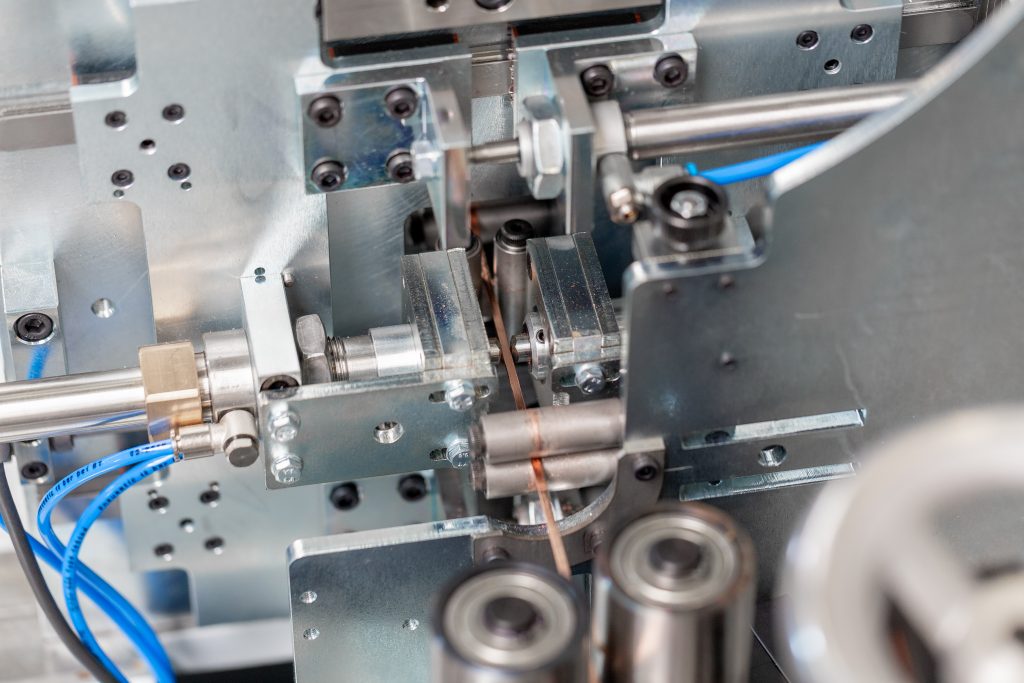

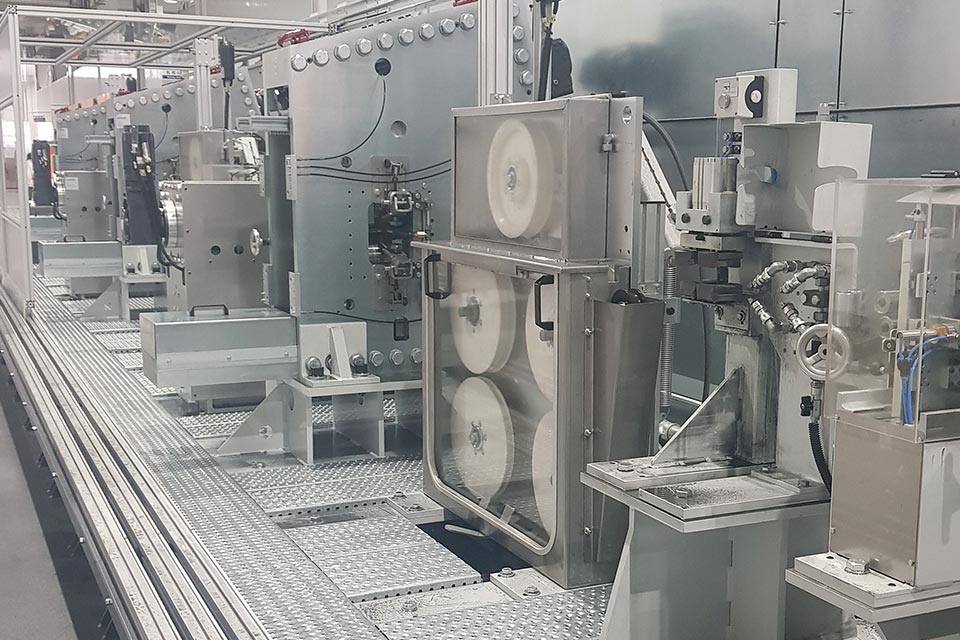

FUHR has been building and developing its own wire measuring devices for several years. They are characterised by precision, robustness and a particularly good cost-performance ratio.

FUHR uses these systems in new mills, but also supplies them for existing and third-party lines.

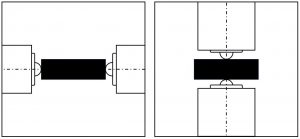

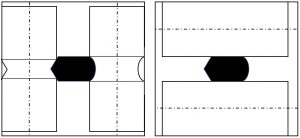

IMS | Inline Measurement System