We contribute to a better, longer and more healthy life

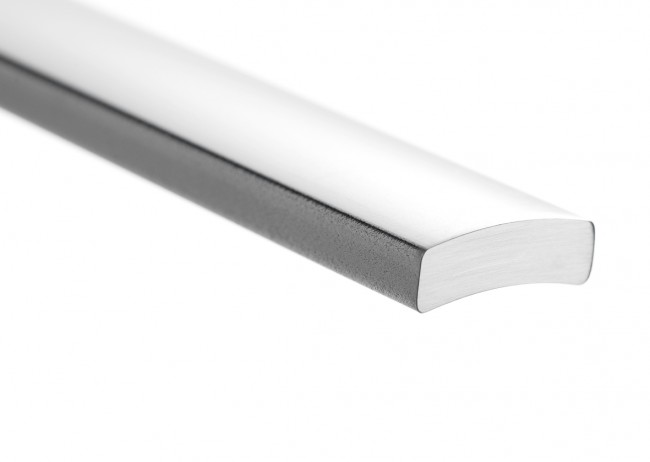

In medical diagnostics, magnetic resonance tomography (MRT) plays a very important role in imaging the structure and function of the tissues and organs of the human body. The key part in these devices are superconductors which produce strong magnetic fields – an important part of the production of these superconductors is the use of cold rolling.

Fractures in the human body are surgically stabilized with high strength, corrosion resistant and often cold rolled implants to give the affected bones the best chance of healing.

From an end-user perspective, we are familiar with the so-called “brackets” that are used in dental medicine as tooth braces, as well as the highly flexible titanium alloys employed in the production of very light frameless glasses.

These are just a few examples of how deeply our rolling technology has also penetrated the area of health. Here too, quality will always prevail.