SMH | Flying spooler

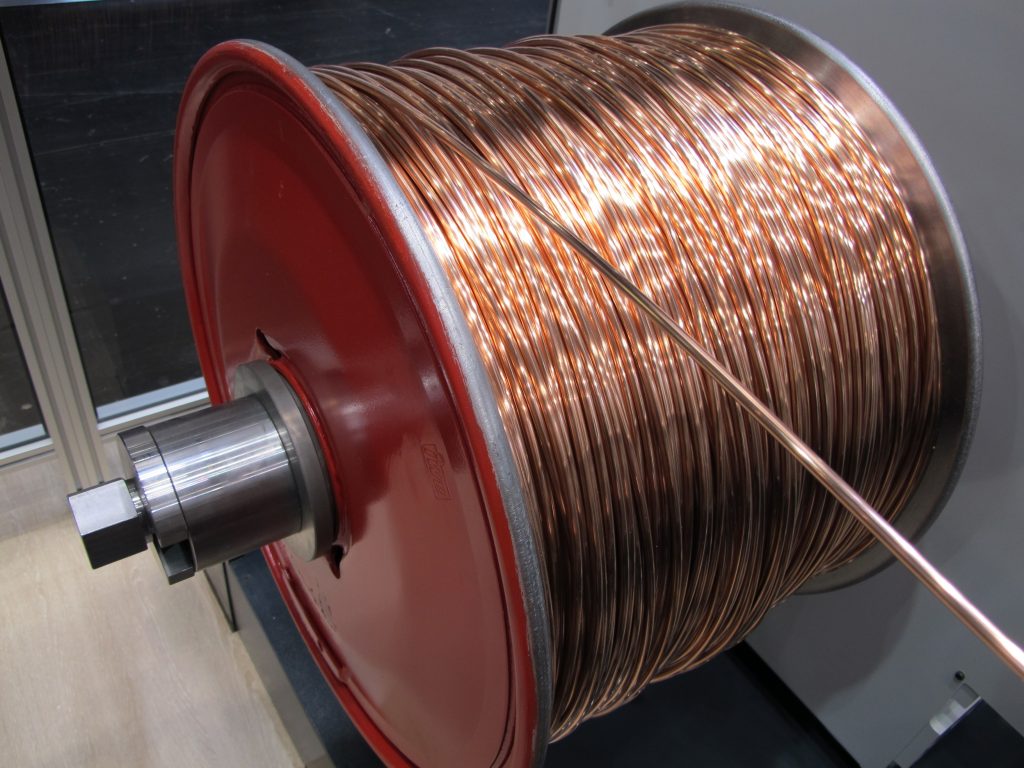

SMH | Cantilever spool mounting

The machines of SMH type are characterized by the one-sided take-up of the material to be wound. This is referred to as a so-called cantilever spooler. It makes these machines less expensive than comparable designs with two sleeves (type SMH-Pi).

A cantilever spooler is only possible when the bore of the reels is big enough for them to be mounted on a stable spindle. This means that coil bore and weight must be in an appropriate relation.

All models are available with and without oscillation.

The machines of SMH type feature modular design and can therefore be supplied in many variations. They are used with reels made of steel, plastic or wood, but can also be equipped with expanding mandrels for the production of coreless coils.

Application examples

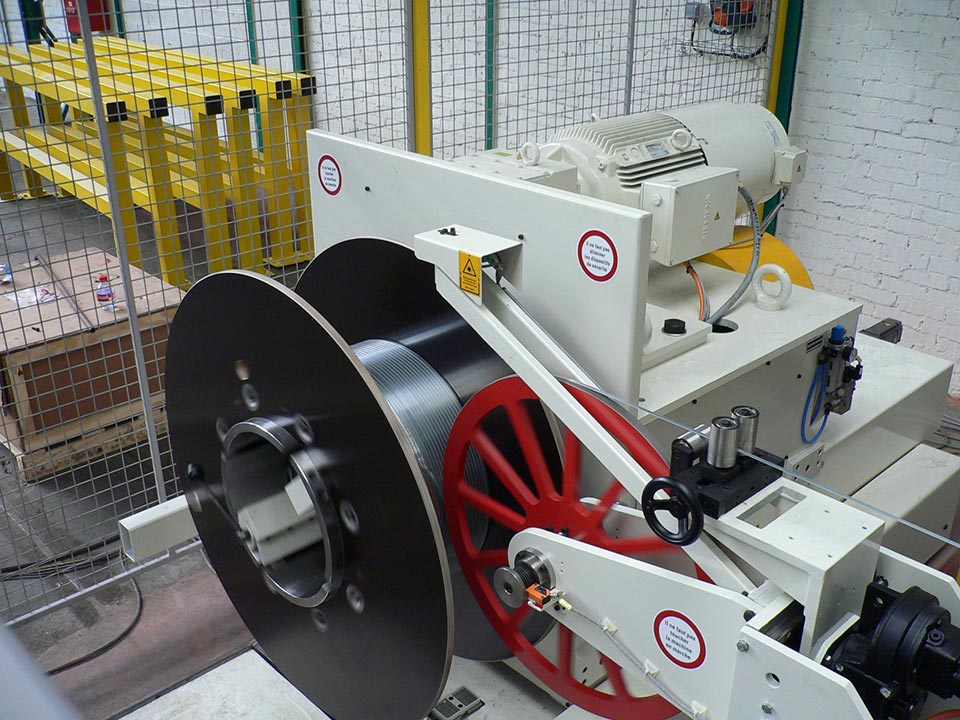

Basic model

- Without oscillation

- With AC-motor drive

- With manually operated spindle for take-up of reels

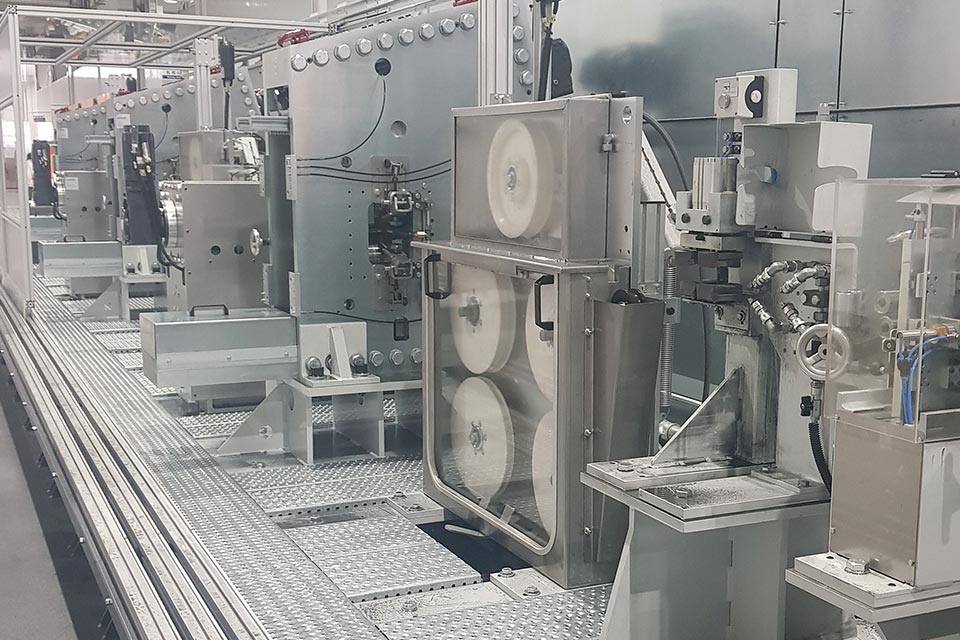

Production of coreless coils of aluminium strip

- Moveable guidewheel for optimized strip guidance at any coil diameter

- High dynamic oscillation-drive with servomotor and ball-screw-spindle

- Rigid coils as a result of an optimized laying software

- Flangeless system for easy strapping and minimized downtime

Expanding mandrel for production of coreless coils

- Hydraulically operated expansion mechanism

- Core diameter adjustable to customer requirements with adapter segments

- Coil width adjustable with electric motor

Precision guidance for flat wires

- Guidance of the wire to the winding point on the reel

- Constant guiding geometry from the first to the last layer

- One single guidewheel for all wire widths

- Gentle wire deflection due to large wheel diameter

- Automatic measuring of empty reels via optical sensors

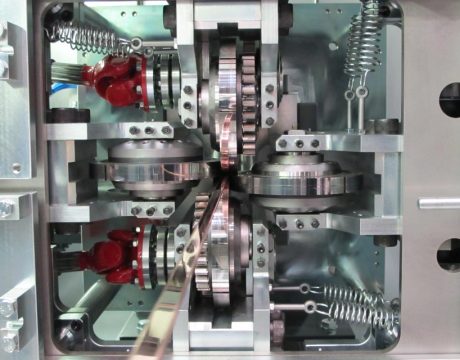

Laying system for rectangular wires

- Faultless layer winding for square and rectangular wire cross sections

- Manual optimization of the winding quality is not necessary

- Automatic measuring of empty reels via optical sensors

Technical data

| Type | Gross load capacity [kg] | max. Reel diameter [mm] | Oscillation stroke [mm] | |

| SMH630-Mo | 1000 | 800 | ||

| SMH630-Mo/O | 1000 | 800 | 630 | |

| SMH1000-Mo | 2000 | 1000 | ||

| SMH1000-Mo/O | 2000 | 1000 | 860 | |

| SMH1600-Mo | 4000 | 1600 | ||

| SMH1600-Mo/O | 4000 | 1600 | 1290 |

Customer specific variations are possible.

Accessories:

- Spindles for take-up of steel, wood or plastic reels

- Expanding mandrels for the unwinding or production of coreless coils

- Hydraulically or pneumatically moved draw rods for actuation of spindles and expanding mandrel

- Lifting tables for loading and unloading

- Wire guidance systems for optimization of layer winding

- Dancers for speed synchronization and tension regulation