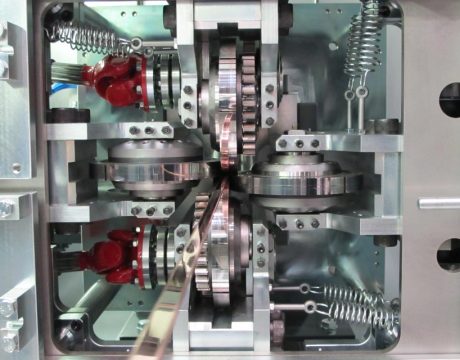

Type WSE | Precision rounding rolling mill

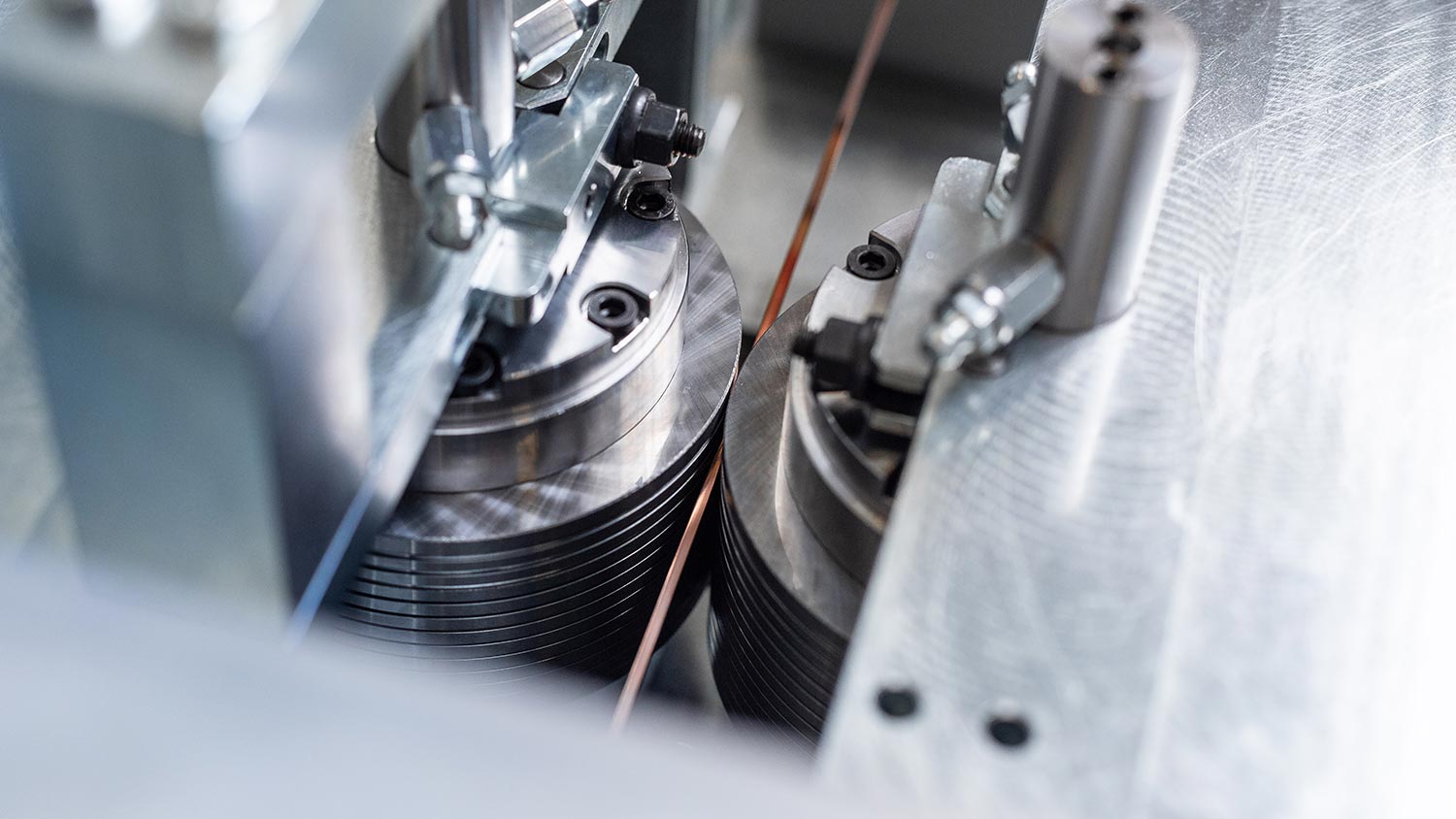

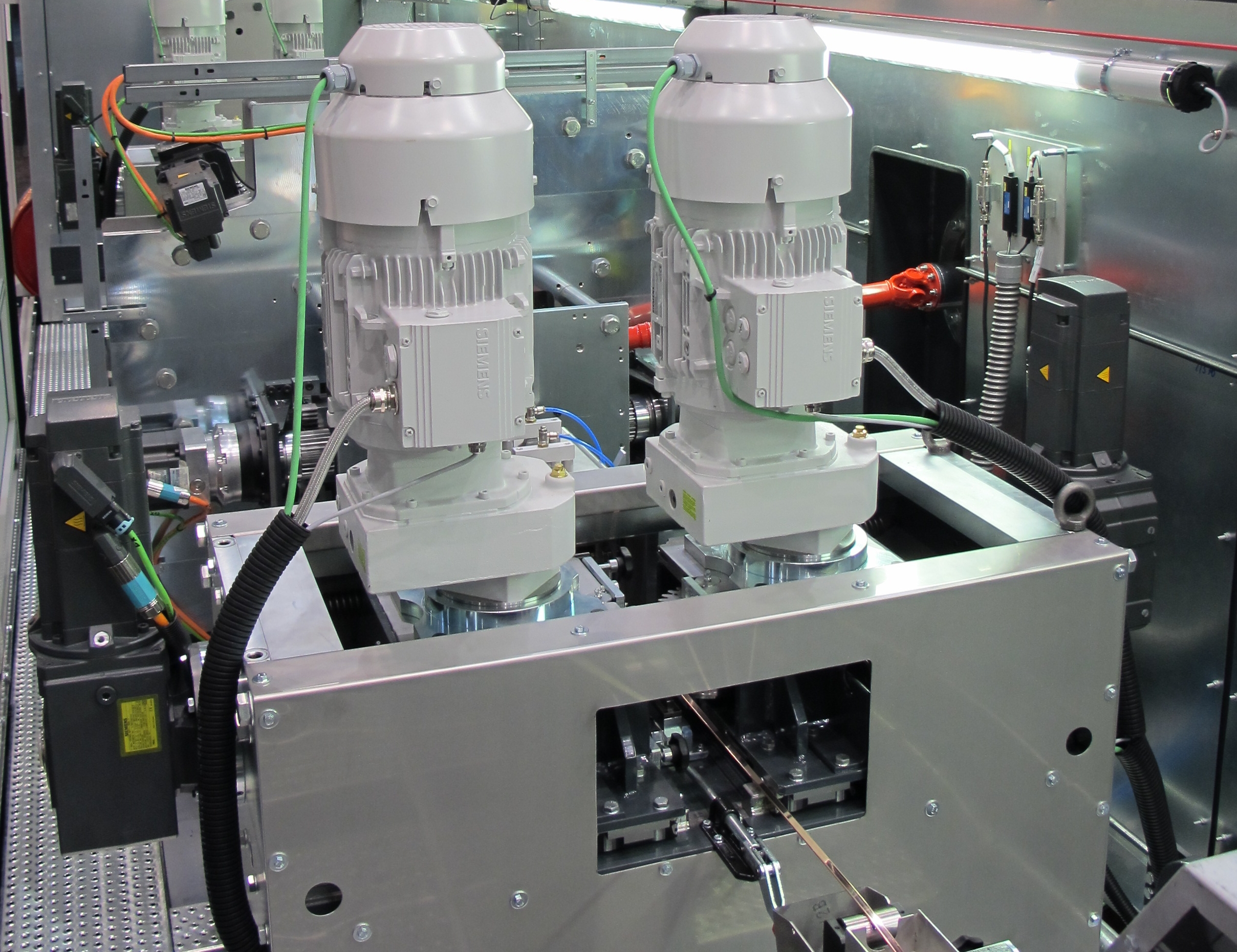

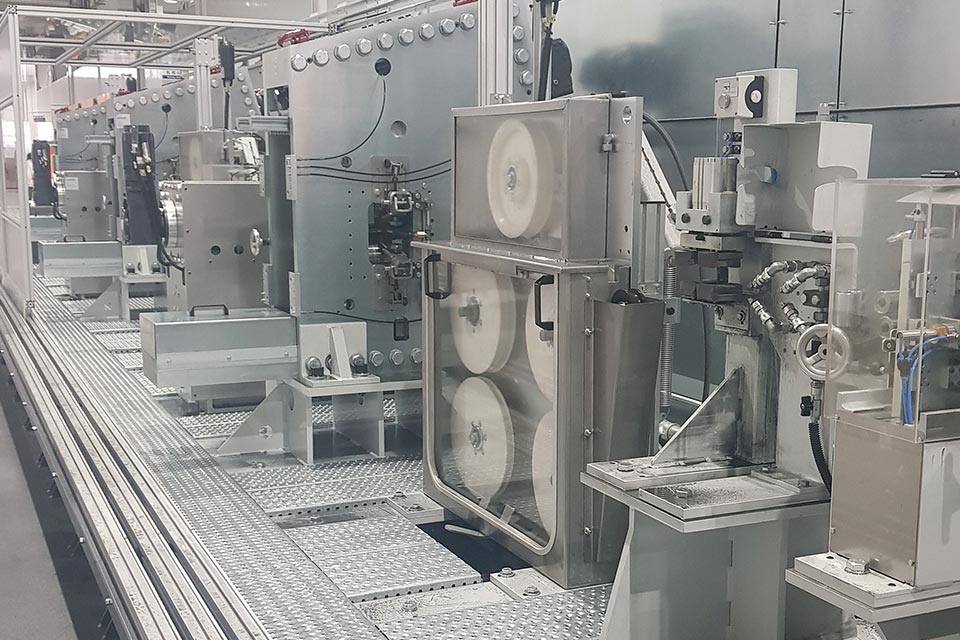

The WSE range is characterized by two rolls with vertical axes. The WSE type rolling mills are used to process the wire to be rolled from the side. Their use is almost always combined with 2-high mills (type WSR) or profile rolling mills (WN, WSN or WST type). The basic mechanical concept with double-sided roll mounting and linear roll adjustment provides this machine with a high stiffness.

In the development of the WSE rolling mill, special emphasis was placed on fast reconfiguration and reproducible settings in order to meet the requirements of flexible production.

Rolling mills of the WSE type have extremely low maintenance requirements. All components are protected from corrosion by galvanization.

WSE | Precision rounding rolling mill